Sunset Plaza completion sets stage for new hotel and restaurants in Flower Mound

Lakeside Village has completed construction on Sunset Plaza, a 217,000-square-foot facility designed to become the centerpiece of a new hospitality and dining destination overlooking Lake Grapevine.

The plaza, located on a 2.5-acre promontory at Flower Mound’s southern tip, offers 360-degree lake views and includes a two-level underground parking garage with 378 spaces. Developers envision the site as a future hub for restaurants, a wedding venue, and eventually a 12-story Marriott Autograph Collection hotel.

“We believe strongly in the magnetism of the lake views from this site,” said Peter B. Stewart, president of Lakeside Village Partners, Ltd. “The views appeal to sightseers, diners, wedding parties, hotel guests, businesspeople, and convention-goers. Seeing is believing.”

The project was originally conceived by planner Kevin Sloan, who imagined an open-air plaza surrounded by restaurants with unobstructed water views. Today, visitors to the site can see nearly all of Lake Grapevine’s 7,200 acres and 60 miles of shoreline, with year-round sunsets over the water.

With the parking garage complete, development partner Jimmy Archie said the next step is to begin construction on a lakeside wedding venue in early 2026, followed by a boutique hotel. “We expect the dining experiences offered by our restaurants to make diners feel like they have been transported to one of their favorite water vacation spots,” Archie said.

General contractor Swinerton oversaw the project’s construction, which presented challenges due to its location near the lake. “Our team is eager to have their first sunset drink at one of the new restaurants on the plaza and see the space come to life,” said Tyler Whittaker, division manager for Swinerton’s Dallas office.

The completion of Sunset Plaza and its garage marks the end of infrastructure development at Lakeside Village, Stewart said.

The post Sunset Plaza completion sets stage for new hotel and restaurants in Flower Mound appeared first on Swinerton.

]]>Powerful backers including Sen. Cruz champion economic impact of McKinney National Airport expansion

New terminal under construction that will make ‘TKI’ region’s third commercial airport

Construction is underway on a new passenger terminal to support commercial flights out of McKinney National Airport and is expected to be completed in fall 2026.

California-based Swinerton Builders began construction on the new 46,000-square-foot terminal on July 18, following years of debate. Work on the $58million facility is expected to wrap up in November 2026, a city spokes person said in an Aug. 4 email.

Commercial flights are expected to begin later that year. The development will turn McKinney National Airport, which goes by code “TKI,” into the third commercial airport in the Dallas-Fort Worth region and the first in booming Collin County.

“This new terminal is not just an investment in McKinney. It’s an investment in the future of North Texas,” McKinney Mayor Bill Cox said during the July 18 ground breaking ceremony.

The project also includes a new aircraft apron, 980 parking spaces with the capacity to expand to 1,450 and a new roundabout to manage traffic from FM546. The entire expansion has a price tag of $79 million, funded by sales tax revenue bonds from the McKinney Economic Development Corp. and McKinney Community Development Corp., a Texas Department of Transportation grant, tax increment reinvestment zone funds, city utility and airport construction funds and airport operating revenue.

The commercial terminal will initially open with four gates, with the potential to expand to six in the future. Airport officials predict serving 200,000passengers in the first year of operation, with an average of three daily departures. By 2031, the airport could serve 1 million passengers a year.

“I was proud to work with the city while drafting the [Federal Aviation Administration] Reauthorization Act and to provide support to help launch this project,” Sen. Ted Cruz said during the July 18 ceremony. “This is a major milestone that will bring jobs and promote economic growth in North Texas.”

The post Powerful backers including Sen. Cruz champion economic impact of McKinney National Airport expansion appeared first on Swinerton.

]]>The post McKinney National Airport Breaks Ground on New Passenger Terminal appeared first on Swinerton.

]]>The post McKinney National Airport Breaks Ground on New Passenger Terminal appeared first on Swinerton.

]]>NEW OPPORTUNITIES TAKING FLIGHT

As the Commercial Hangar and Inspections Building project at McKinney National Airport continues to make headway, Swinerton deepens its commitment to the communities of North Texas with another win at the site—the ground-up Commercial Airport Terminal.

Last year, Swinerton broke ground on a pivotal project to expand the transportation capacity of North Texas. The project is delivering a new 40,000 square foot hangar, Corporate Hangar 10, and a new 3,200-square-foot U.S. Customs and Border Protection facility at McKinney National Airport, which will allow international flights to land and taxi directly to customs, expediting and streamlining the process for travelers.

The project taps architecture and engineering team JRMA and Garver and is being uniquely delivered under a Public- Private Partnership (P3) led by developer Griffin Swinerton. As population booms exacerbate infrastructure gaps across the country, P3 deal structures are quickly emerging for their ability to leverage the strengths of the private sector to finance, build, and manage public infrastructure, typically offering a more balanced allocation of risk, opportunity for innovation, and streamlined project execution with cost and performance guarantees. This opens up opportunities for counties and cities to deliver world-class facilities for their communities without placing unnecessary burden on local taxpayers.

For the City of McKinney, the P3 development method is enabling the City to maintain ownership and oversight of the facilities, while tapping Griffin Swinerton’s network of resources and expertise to design, permit, and construct the new facilities alongside Swinerton.

George Fuller, Mayor of McKinney, says, “The Swinerton and Griffin Swinerton team has done an excellent job partnering with the City to facility a smooth P3 delivery process, and we’re excited to see the results.”

New Commercial Terminal Project Expands Impact in Texas

Another pivotal project will reshape the airport, this time opening it up to commercial travel. The City has awarded Swinerton the contract for a 45,000-square-foot commercial airport terminal facility at McKinney National Airport, alongside design and engineering team Corgan and Garver.

Pending final city council approval, the terminal will include three gates for arrivals and departures—with space to accommodate future expansion to five—and will feature a public arrival check-in area, concessions, hold rooms, airline support areas, ramp operations, and rental car counters. Other plans for the terminal include food and beverage concessions, passenger holding rooms, above-ground jet fuel tanks, other extensive airside site development, and a parking lot with up to 1,500 spots.

The City estimates that the terminal could see 200,000 passengers in its first year of passenger service, and up 1 million annual passengers by its fifth year. This estimate trends inline with the recent population boom in the Dallas area. The metroplex consistently ranks among the fastest growth metropolitan areas in the United States. Of the top 10 fastest-growing cities in the country ranked last year by the U.S. Census Bureau, four were in Collin County, which stretches from North Dallas and includes the communities of McKinney, Plano, and Celina.

McKinney National Airport will mark the Dallas-Fort Worth metroplex’s third regional airport and has been strategically planned to serve these fast-growing cities in North Texas. The airport will provide greater convenience and flexibility to residents of Collin County and nearby communities— while also easing the burden on Dallas Love Field and Dallas Fort Worth International Airport, the latter of which was ranked the third busiest airport in the country last year by the Federal Aviation Administration.

As a community contractor with national reach, Swinerton is proud to continue its commitment to the Dallas-Fort Worth metroplex and invest in the continued growth and prosperity of North Texas.

The post NEW OPPORTUNITIES TAKING FLIGHT appeared first on Swinerton.

]]>Safety Story: Tyler Whittaker

In honor of Safety Week,?we sat down with Swinerton employees to find out what safety means to them.

Tyler Whittaker,?Vice President and Dallas Division Manager,?sheds light on why being intentional about safety is so important to his team’s culture and collective success.

Safety Q&A

Could you share about your career at Swinerton??

I have been in construction about 18 years, and my last seven years have been with Swinerton. I started as a senior preconstruction manager in Colorado and continued in preconstruction prior to accepting the Division Manager position here in Dallas in 2021.

As a division manager, how do you view your role in Swinerton’s safety culture??

I see my role in safety as twofold: providing resources and being deliberate.?

I need to ensure that my teams have all the necessary resources within the division to keep safety as their number one priority. This includes building a robust team of safety professionals, hiring field superintendents who align with our safety culture, and providing our self-perform teams with the safety support they need every single day. Training our craft and being proactive is an intentional focus of our teams.

I also work to stay as intentional as possible with respect to safety and encourage our teams to do the same. When we meet for our safety-specific job walks or have our safety department meetings, I work with the team to ensure we discuss safety protocols in detail and not focus on execution.?

What preventative practices have you put in place in Dallas??

In Dallas, we hold monthly safety walks that include the entire leadership team, and we only focus on safety during that time – not schedule, budget, or other topics. It is important to walk the jobs, not be distracted with project execution, and to have an eye towards safety risks.? We talk about safety trends from the prior month – both locally and throughout the division and region – looking at specific on-site risks. We discuss strategies we’ll need to implement as we go to reduce those risks and keep everyone safe.

The operations manager and director also have weekly leadership meetings with our division safety manager where they look at job site trends, analyzing any incidents we’ve had and putting additional preventative measures in place.?

What do you believe sets Swinerton’s safety culture apart in the construction industry??

Given we’re 100% employee owned, we’re all invested in each other’s success and performance. We take pride in making sure we all go home to our families at the end of the day. We’re all looking out for each other because we really care for one another. I really see this show up in my self-perform teams, because it’s crucial that they watch out not only for themselves, but one another.

You’re in the process of building out your safety training program in Dallas. What elements are you keeping top of mind as you build this program??

Going back to being intentional, training is something we’re very intentional about. Maintaining focus and clarity with our teams is crucial, especially since we are self-performing general contractors, which means our safety culture needs to reflect that our employees are in the field doing the work – versus managing subcontractors. Our training emphasizes quality, execution, and safety standard operating procedures (SOPs), including equipment and safety processes that our craft teams need to know.?

We’re also intentionally growing the safety team in our division. Our Division Safety Manager, Ryan Barnes, is the longest-tenured person in the Dallas division, and he’s been instrumental in helping build our safety program and culture here. His expertise coming from the Craft side of the field has helped us immensely in building our teams and encouraging them to always prioritize safety.?

Lastly, recognizing a team member for going above and beyond is crucial. Showing up on the job site to shake their hand and thank them ensures they understand that their actions, performance, and focus on safety are noticed, appreciated, and valued. Being present and taking time to acknowledge their efforts makes a significant impact. That on-site presence from all our leaders goes a long way in the field.

The post Safety Story: Tyler Whittaker appeared first on Swinerton.

]]>Rowlett breaks ground on new municipal complex with city hall & police

The City of Rowlett broke ground on its new Municipal Complex on April 26, a project that represents the largest capital investment in the city’s history.

Hosted at Herfurth Park, the groundbreaking drew residents, elected officials, project partners, and city staff to commemorate the beginning of construction on what is anticipated to become a cornerstone of Rowlett’s civic life.

There were also food trucks, bounce houses, a DJ, giveaways, and a commemorative coin for early attendees. During the ceremony, community leaders were joined by representatives from design firm Hoefer Welker, construction firm Swinerton, and engineering teams from Lamb-Star, Terracon, and SAM, all of whom shared their excitement for the project.

According to a release, the new Municpal Complex will be located on approximately 25 acres at 4601 Centennial Dr. This facility will house the new City Hall, city administrative offices, police department headquarters, fire administrative offices, and animal shelter. The grounds will include walking trails, community gathering spaces, playgrounds, and a dog park.

The post Rowlett breaks ground on new municipal complex with city hall & police appeared first on Swinerton.

]]>Celina parking garage construction advances on schedule

Development of the new downtown parking garage is moving forward on schedule, the city of Celina reported, with its construction partner, Swinerton, making progress on level three.

The city stated that in the coming weeks, the focus will be on placing concrete decks, a milestone that will enhance parking capacity.

Swinerton also officially broke ground on the new Downtown Center.

Initial construction activities will include excavating the basement area, installing the soil retention system and drilling foundation piers. Additionally, extensive hauling operations will begin to remove significant volumes of soil from the site, resulting in increased truck traffic along FM 455 during this phase.

Assistant City Manager Kim Brawner said crews have begun pouring columns for the fourth deck and will soon pour concrete for the fourth deck.

Swinerton has also dug the foundation and basement of the Downtown Center, reaching a depth of 5 feet.

The city approved the $19.3 million garage in September 2024 and the Downtown Center project in February.

The post Celina parking garage construction advances on schedule appeared first on Swinerton.

]]>Flower Mound’s Lakeside Village breaks ground on underground garage to anchor waterfront dining district

Swinerton is vitally involved in developing the underground parking garage for Flower Mound’s Lakeside Village, an essential part of the area’s transformation into a waterfront dining and entertainment district. The $16 million garage will offer parking for lake-view restaurants, a public plaza, and trails.

This infrastructure project is part of a more extensive $60 million expansion to enhance the village’s southern section. The garage’s completion is expected in April 2025, and it will significantly improve access and the surrounding environment.

The post Flower Mound’s Lakeside Village breaks ground on underground garage to anchor waterfront dining district appeared first on Swinerton.

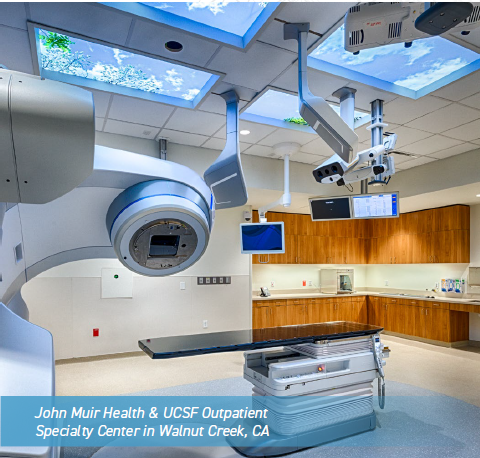

]]>As a community contractor with national reach, Swinerton understands the unique demands of building some of our society’s most impactful and widely used infrastructure, including healthcare and life sciences facilities, housing for our vulnerable populations, and transportation hubs. Through vertical leadership and resources, we deliver the consistency and efficiency these market sectors require.

From our earliest days, Swinerton has lent our flexibility to a diverse array of product types and clients: from rebuilding hotels and commercial districts after natural disasters, to our expansion into complex industrial projects in the 20th century, to solidifying our place as a modern-day industry leader in sustainable mass timber construction.

Today, Swinerton is proud to provide premier commercial construction services to nearly 20 market sectors. Several of these markets—including Healthcare, Life Sciences, Affordable Housing, Aviation, and Parking Structures—comprise a large portion of our portfolio in multiple regions nationwide, necessitating centralized resources. These sectors are also essential to our daily lives, serving our society’s needs for health, shelter, and transportation.

To address the unique demands of these markets, Swinerton has centralized its resources and appointed National Market Leads to guide the overall focus and approach, enhance the consistency of project delivery from region to region, and reduce onboarding time for project teams by equipping them with the right training, resources, and processes to deliver on specialized market-specific needs.

To address the unique demands of these markets, Swinerton has centralized its resources and appointed National Market Leads to guide the overall focus and approach, enhance the consistency of project delivery from region to region, and reduce onboarding time for project teams by equipping them with the right training, resources, and processes to deliver on specialized market-specific needs.

“A national approach enables effective management, ensuring that we allocate resources where they are needed most,” says Chris Morris, leader of Swinerton’s National Healthcare market. “Recognizing that each division has its unique strengths and challenges, our team provides tailored support to address these specific needs. Whether it involves delivering in-depth healthcare market research, assisting with project management, or offering targeted training and development, we reduce the learning curve for local divisions and ensure that their teams are equipped with the necessary tools and resources to thrive.”

While projects across the country will always have regional considerations, such as different code requirements and jurisdictional agencies, many markets also have specific inherent industry needs that must always be considered no matter the project size, location, or complexity. For example, research-focused clients often operate in regulated, complex industries and require partners who understand the critical nature of their work, says Swinerton’s National Life Sciences Director, Marcella Ayala.

“From an operational perspective, Swinerton provides a solid backbone through centralized resources, including specialized MEP expertise and technical support, quality assurance, and safety protocols. These resources ensure that no matter where our Life Sciences clients’ projects are located, they receive the same high level of service and technical excellence that their industry demands,” Marcella adds.

As clients seek to answer what is next for their growth—whether rapidly expanding their own operations, or advancing their industry with new innovations—having a national, enterprise construction firm with the capabilities to answer a diverse set of needs is critical.

In addition to national quality and safety programs and centralized MEP expertise, Swinerton is capable of self-performing some of the most critical trades that drive a project, including concrete and drywall. In addition, the firm brings extensive mass timber expertise alongside the partnership of its mass timber affiliate, Timberlab. These capabilities can help drive cost and schedule efficiencies for many market sectors, but have proven especially valuable for affordable housing, where budget, community engagement, and sustainability are at the heart of nearly every project.

“Self-perform plays a huge role in this work,” says Patrick Otellini, Swinerton’s National Affordable Housing Director. “We have struck a delicate balance between complying with the Local and Small Business Enterprise goals for these projects, while identifying solid scopes of work for our self-perform group to help drive down cost and create schedule efficiencies. We also interface a lot with Timberlab, since many of these clients are looking at ways to build more sustainably.”

Recently, a Seattle-based architect who helped author changes to the 2021 International Building Codes (IBC) collaborated with Swinerton and Timberlab to build Seattle’s first mass timber mid-rise workforce housing structure under the new codes. The partnership testifies to how Swinerton’s integrated offerings are not only advancing the future of certain market sectors, but the construction industry as a whole.

Swinerton’s ability to self-perform work is also critically tied to the success of one of its largest national platforms: parking structures. Rather than a market in and of itself, Director of Parking Structures Jeff Goodermote refers to the structures he constructs as a specific “product” that intersects with and supports every other market that Swinerton works in.

“The parking structures sector is a little different from other market sectors, which may include different product types all under one umbrella. For example, aviation has landside and airside operations. Healthcare has acute and non-acute facilities. Compared to those markets, parking is a truly specialized, niche field,” Jeff says.

The group’s complete expertise in parking structure products can be largely attributed to the success of Swinerton’s self-perform concrete group, he adds.

“We have invested in a substantial amount of self-owned concrete formwork that is specific to concrete parking structures. Leveraging our design-build or progressive design-build expertise, we can design a parking structure around our specific formwork, which often results in a considerably lower price than market rate,” Jeff continues. “We have even shipped our formwork over the Pacific Ocean to deliver concrete projects in Hawaii. In addition to our extensive collaboration with our self-perform concrete teams, we are beginning to engage our drywall teams to self-perform some of the fa?ade treatments of our parking structures to round-off our thorough, end-to-end expertise in this product type.”

Over the past decade, the National Parking Structures group has delivered on a number of aviation parking structures throughout California and Colorado, not only bolstering its own portfolio but also the project experience of the National Aviation group. This has been a catalyst for success in other divisions, such as Texas and the Southeast. Additionally, intergroup collaboration between Swinerton’s national market platforms allows the firm to leverage its focus on enhanced efficiency, knowledge-sharing, and commitment to drive value by bridging often-fragmented scopes of work.

“Airport decision-makers are looking for partners who can be problem-solvers that understand both the complex requirements of airport construction and the unique aspects of the local market. We are thrilled to regularly partner with other Swinerton target markets like National Parking Structures,” says Carrie Shaeffer, National Director of Aviation.

“Clients benefit from a collaborative approach because we can provide innovative parking expertise and capabilities that also align with the specific nuances of sensitive airport environments informed by our National Aviation group,” Jeff adds.

Modern construction is demanding. Through our national market platforms, Swinerton ensures that our regional teams have the skills, resources, and support they need to tackle projects in a wide range of sectors. Furthermore, our coast-to-coast expertise and capabilities provide opportunities for clients seeking consistency and efficiency in their project delivery nationwide.

The post Delivering Crucial Infrastructure on a National Scale appeared first on Swinerton.

]]>Mass Timber Buildings: A New Approach to Sustainability and Net Zero Goals

Mass timber is quickly becoming a solution as the number of public institutions and private developers pledging to attain net-zero carbon emissions increases. Whether they are leaning on public-private partnership (P3) or traditional delivery methods, owners and developers are recognizing the benefits of wood as a versatile, sustainable, and structurally efficient feature for their projects. With public and private support for this renewable resource, experts believe mass timber could challenge steel and concrete as favored construction materials.

“Mass timber offers cost and value considerations that developers and clients see as benefits. Mass timber supports regional economies, saves time on the speed of construction, and is a renewable resource—with the added benefits of improved daylighting and interior aesthetics, which benefits the health and well-being of the end-user as well,” said Swinerton Builders (Swinerton) Pacific Northwest Regional Director of Preconstruction William Silva.

For example, at Northlake Commons, the utilization of mass timber estimates 1,990 metric tons of avoided CO2e (carbon dioxide equivalent) emissions, with a total carbon benefit of 2,920 metric tons; this is equivalent to removing 558 cars from the road or to the energy required to operate 249 homes for an entire year. It is also estimated that forests in the U.S. and Canada can regrow the equivalent wood volume in four minutes.

Swinerton’s early commitment to mass timber began in 2016 with the design, permitting, and construction of the then largest mass timber office building in the U.S.—First Tech Federal Credit Union Oregon Corporate Campus—which was delivered four months faster and four percent cheaper than structural steel.

In a short period, Swinerton has become known for taking on and successfully delivering some of the most challenging mass timber projects in the country. With the number of mass timber projects expected to double every two years, Swinerton has assembled an unparalleled knowledge base and robust internal resources that are sought after by design teams and owners who want to capitalize on the lessons learned from other projects.

While building designs will continue to push toward net zero energy, reducing operational carbon through better energy efficiency and cleaner energy sources, there is growing policy and regulation emphasizing the importance of reducing the embodied carbon of our infrastructure as well. Structure and foundation make up over half of a building’s embodied carbon footprint, so they are often targeted first for reductions. Every metric ton of wood used in place of concrete and steel in the structure is estimated to avoid 3.9 metric tons of CO2 emissions, and this is compounded by the fact that mass timber buildings are lighter and reduce the carbon (i.e., concrete) in the substructure.

Life-cycle assessment (LCA) is the industry tool for evaluating the embodied impacts of a building design, but what it cannot account for is the potential carbon “storage vault” mass timber infrastructure offers cities. Mature forests are maximizing their carbon storage, while growing forests are maximizing their carbon sequestration. By sustainably harvesting trees off the landscape and storing that carbon in wood structures for the life of the buildings, forests are allowed to sequester carbon more rapidly from the atmosphere and avoid releasing a large portion of the carbon stored in the removed trees.

While the softer benefits of mass timber, sustainability, and aesthetics frequently lead project teams to want to use a mass timber solution, the construction benefits are often what enables them to happen.

Swinerton recognizes the challenges of developing a project around a new structural system and brings its expertise to teams seeking creative solutions to make a mass timber project financially viable. Swinerton’s approach is to direct efforts toward reducing overall construction cost through smart and informed selections of not just the structural system but also to look at how to leverage complementary benefits in building mechanical, electrical, envelope, and interior systems to help achieve low energy goals.

“We can control costs through early assessment on project alignment with building code and efficient structural layouts that allow for complementary benefits with other building systems and maximize prefabrication,” added Silva.

Because Swinerton is a national leader in numerous construction market sectors, it combines market sector knowledge with mass timber advantages to bring beneficial outcomes for its clients. Swinerton has pioneered mass timber solutions in market sectors, including affordable housing, aviation, civic, community college, corporate accounts, healthcare, higher education, life science, office and more.

5 Examples of Swinerton’s Mass Timber Project Experience

Northlake Commons, Seattle, WA

Swinerton’s Northlake Commons highlights the sustainability of mass timber in workplace construction. This 275,000-square-foot, LEED? Platinum-certified building incorporates mass timber columns, beams, and cross-laminated timber (CLT), showcasing how renewable materials can support both structural durability and environmental responsibility. Built in collaboration with Timberlab, a Swinerton affiliate, Northlake Commons’ timber was carefully chosen for its capacity to age beautifully while creating a warm, health-focused environment. Mass timber, significantly lighter than concrete and steel, reduces carbon emissions by up to 75%.

Beyond the use of wood, the building’s design maximizes water and energy savings, contributing to a 27% reduction in electricity usage and conserving over 700,000 gallons of water annually. Further, a significant 96% of construction waste was recycled, minimizing environmental impact. This commitment to sustainable mass timber not only enhances the building’s aesthetic and structural integrity but also reinforces Northlake Commons as a model for eco-friendly development in modern architecture.

Childcare Center, Boise, ID

The new 19,347-square-foot single-story childcare center is a groundbreaking example of the benefits of mass timber in early education. Imagine nine lively classrooms with stunning vaulted ceilings, where clerestory windows flood the space with natural light, accentuating the warmth of timber columns and beams. Outside, timber overhangs create inviting play areas, blending seamlessly with nature.

This center isn’t just beautiful—it highlights sustainability. It combines mass timber with additional eco-friendly exterior materials, native landscaping, and cutting-edge energy-efficient features like low-VOC paint, smart thermostats, and LED lighting, seeking to achieve LEED? Gold certification. This innovative approach ensures a healthy, inspiring environment for children to learn and grow.

Sunnydale Community Center, San Francisco, CA

A vibrant new 30,000-square-foot neighborhood community center is a stunning two-story mass timber marvel. It offers a mix of spaces, such as a teaching kitchen, study areas, a recording studio, and a living room for community gatherings. The Sunnydale Community Center also hosts new facilities for Boys & Girls Clubs of San Francisco and Wu Yee Children’s Services, significantly boosting their capacity to provide childcare and youth programs.

Designed for LEED? Gold certification, the center emphasizes sustainability and biophilic design, using CLT and glulam for structural, aesthetic, and eco-friendly qualities. The exposed wood structure not only speeds up construction but also reduces waste and creates a warm, inviting atmosphere.

This project revitalizes the neighborhood, demonstrating the potential of mass timber construction and environmental responsibility with beautiful, impactful construction.

Live Oak Bank Building 4, Wilmington, NC

In Wilmington, NC, a new development is welcoming employees—a four-story, 67,000-square-foot constructed entirely from mass timber. This ambitious project is one of the largest of its kind in the United States, slashing the building’s carbon footprint by up to 60%. Nestled among trees and overlooking an expanded pond, Live Oak Bank Building 4 is a harmonious blend of nature and innovation. The design incorporates numerous biophilic elements, aiming to foster a happier, healthier, and more productive work environment. The building is on track to achieve LEED? Silver certification, highlighting its commitment to sustainability and eco-friendly design.

In Wilmington, NC, a new development is welcoming employees—a four-story, 67,000-square-foot constructed entirely from mass timber. This ambitious project is one of the largest of its kind in the United States, slashing the building’s carbon footprint by up to 60%. Nestled among trees and overlooking an expanded pond, Live Oak Bank Building 4 is a harmonious blend of nature and innovation. The design incorporates numerous biophilic elements, aiming to foster a happier, healthier, and more productive work environment. The building is on track to achieve LEED? Silver certification, highlighting its commitment to sustainability and eco-friendly design.Responsive Arts & STEAM Academy, Denver, CO

Additional Reading: Contractors are Partners for Achieving Sustainable Development Goals

The post Mass Timber Buildings: A New Approach to Sustainability and Net Zero Goals appeared first on Swinerton.

]]>