Swinerton Completes First Phase of Security Enhancement with Spokane Valley and Liberty Lake’s Central Valley School District

The first five of ten planned schools receive modernized entry vestibules as part of a district-wide initiative to enhance campus safety.

Swinerton Builders (Swinerton) has completed the first phase of a $2.8 million, district-wide initiative to upgrade front entry vestibule systems for Spokane Valley and Liberty Lake’s Central Valley School District (CVSD). The initial five of ten planned upgrades are now in place, reflecting CVSD’s commitment to creating safer, more controlled access points at its schools. These upgrades will be completed at eight elementary schools and two middle schools across the district.

The progressive design-build project included redesigning and modernizing main entry points, including restrooms, reception areas and administrative spaces to enhance safety, functionality and overall appeal. Entry point upgrades included locking double doors and video monitor systems. The first five schools completed in the series included Greenacres Middle School, Broadway Elementary School, Liberty Lake Elementary School, Progress Elementary School, and Summit School. The other five schools are set to be completed in the summer of 2026.

Partnering with Architects West, Swinerton successfully delivered a project that meets a growing need for school and campus security. From the planning stages to project turnover, Swinerton worked closely with CVSD to ensure the upgrades were completed on time before school was back in session. This project represents Swinerton’s ongoing commitment to creating educational environments that allow students to thrive and provide them with the best opportunity for success.

“This project is a very personal one for the Swinerton Inland Northwest team,” said Jeremiah Shakespeare, division manager and vice president of Swinerton’s Inland Northwest division. “Many of us have family and friends who live in, work in, and attend schools in the district. We are grateful that our work will provide students, staff, and families with safety and peace of mind on a daily basis.”

The CVSD ribbon cuttings were held on August 24 and September 5 and were attended by the Superintendent, local politicians, school staff, faculty, board members, students and community members. Swinerton is proud to be ringing in the new school year by providing increased safety for the students, staff, and faculty in the greater Spokane Valley and Liberty Lake area.

Swinerton has been deeply involved in shaping the Inland Northwest built environment, delivering $250 million in commercial projects specializing in aviation, civic, education, gaming, healthcare, hospitality, and office ground-up and renovations. They have also been identified as a market leader in preconstruction services and alternative delivery and for having the unique ability to provide local and national expertise in those areas, as well as development, public-private partnerships (P3) and design-build approaches to the most challenging projects.

The post Swinerton Completes First Phase of Security Enhancement with Spokane Valley and Liberty Lake’s Central Valley School District appeared first on Swinerton.

]]>Safety Story: Matt Nilsson

In honor of Safety Week, we sat down with Swinerton employees to find out what safety means to them.

Following his recent promotion to Regional Director of Safety for the Pacific Northwest, Matt Nilsson discusses his journey from Safety Intern to Regional Director, his approach to building a safety culture, and why fostering human connection is at the heart of workplace safety.?Matt oversees safety operations in Seattle, Portland, Spokane, and Boise.

Safety Q&A

How did your journey from intern to director shape your approach to construction safety leadership in Seattle?

I started as a Safety Intern with Swinerton back in 2006 while studying at Central Washington University, where I was pursuing a Bachelor of Science in Safety and Health Management. Most of my internship was spent at the Ilani Casino project, and I fell in love with the company culture immediately. Unlike my colleagues who interned elsewhere, I felt like part of a family at Swinerton rather than just a number.

I actually fell into safety somewhat unexpectedly. I originally wanted to be a police officer and was studying law justice, but quickly realized it wasn’t for me. When I took a construction-focused industrial engineering technology class, something clicked. My professor suggested safety might be a good fit for me, and he was right.

Safety appealed to my protective instinct – I’ve always been someone who prefers working behind the scenes. During my time at Central, I was profoundly affected when an 18-year-old worker was electrocuted and lost his life while working on a ship. That tragedy solidified my commitment to safety work. I never wanted another family to experience that kind of grief. At its core, safety is about being another set of eyes for workers, looking out for them and ensuring they return home to their families each day.

How do you foster open communication within your teams to promote a stronger safety culture?

Safety is never a “check-the-box” function. Every project has unique circumstances that require different safety strategies. The key is establishing a collaborative planning process that begins well before construction starts.

We focus on pre-planning with the project teams, particularly with Superintendents. We sit down together to review the schedule and develop Job Hazard Analyses (JHAs) for all Swinerton tasks and high-hazard subcontractor activities. This collaborative approach gives everyone a holistic understanding of what requires our focused attention.

I’m a strong believer in overcommunicating the “why” behind safety practices. When project teams understand the reasoning, they’re more equipped to foster that culture and implement safety practices in the field. We also work extensively with trade partners – especially smaller ones who might not have their own safety personnel – to coach and mentor them. My goal is to make the entire industry safer, one project at a time.

For me, safety isn’t about being the “safety cop” who’s just looking to write people up. I’m a safety professional focused on coaching and mentoring both our people and our trade partners. I can’t expect everyone to know every standard because, even after years in this business, I’m still learning. By taking this educational approach, we improve safety standards across the industry.

How does Swinerton’s approach to both mental and physical well-being contribute to a safer work environment?

Mental Health Awareness is something I’m passionate about. In Seattle, we partner with Associated General Contractors (AGC), and I’ve worked closely with Mandi Kime, AGCW Director of Safety, who heads up mental health awareness initiatives for AGC of America. We’ve brought her to various projects and department meetings to provide training on mental health awareness.

At Swinerton, we create toolbox talks specifically focused on mental health awareness for our craft workers and project staff. During Safety Week (May 5-9), we conduct daily talks rather than our usual weekly toolbox talk, with most focused on mental and physical well-being.

But sometimes it’s the simplest things that matter most, i.e. stopping to have a genuine conversation with craft workers, asking how they’re doing, and showing appreciation for their work. Construction has traditionally had the mindset of being tough and hiding feelings, but the industry is doing a fantastic job debunking that myth.

We also incorporate physical well-being initiatives. In our office, a group of us take walks around the building every few hours – just taking a break, enjoying the sunshine, and mentally checking out from work for those five minutes can make a huge difference.

What safety practice do you consider most essential?

Getting back to the safety basics. At Swinerton, we’ve found that focusing on the fundamentals consistently is what truly keeps people safe day in and day out.

Our Safety Program rests on a firm foundation of effective, industry-recognized strategies that promote safety and wellness on and off the jobsite. Through comprehensive safety plans, meticulous pre-planning, ongoing training, and daily mentoring, we maintain incident rates substantially lower than industry averages.

We emphasize clear communication when identifying, analyzing, and preventing risks. Our findings are shared with management, staff, supervisors, and workers to ensure continuous improvement in safety practices. Through ongoing assessment and planning of the jobsite and the site’s safety plan, we adjust for real-world conditions, whether large or small.

How do you recognize and show appreciation for team members who demonstrate safety excellence?

In the Pacific Northwest region, we recently started a recognition program featuring special lime green high-visibility shirts with the “Your Family Needs You” (YFNY) logo. These shirts stand out from our standard orange ones and are awarded to employees who go above and beyond with safety. The two individuals in a recent photo I shared on LinkedIn received these shirts after they used their Stop Work Authority to intervene when they saw a subcontractor employee getting dangerously close to a power line while operating a lift. They stopped the work before an incident occurred. Along with the shirt, we send a thank-you letter to their home, signed by our Division Manager and Operations Manager, expressing appreciation for their commitment to safety.

On specific projects, we also implement various recognition programs – from monthly crew recognition with lunch and photos displayed on the jobsite to supervisors carrying gift cards to distribute when they see good safety practices. Some clients even get involved, like the Tulalip Tribe recently hosted a barbecue just to thank everyone for working safely while not disrupting casino operations.

These recognition efforts are about creating a positive safety culture. Many companies misunderstand safety as only being about write-ups and negative consequences, but we take a positive approach – recognizing our people for doing things the right way.

?

The post Safety Story: Matt Nilsson appeared first on Swinerton.

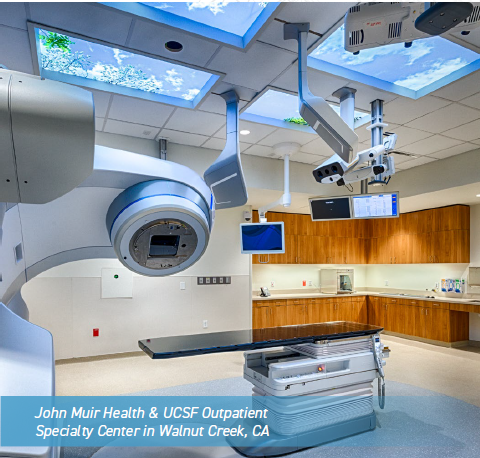

]]>As a community contractor with national reach, Swinerton understands the unique demands of building some of our society’s most impactful and widely used infrastructure, including healthcare and life sciences facilities, housing for our vulnerable populations, and transportation hubs. Through vertical leadership and resources, we deliver the consistency and efficiency these market sectors require.

From our earliest days, Swinerton has lent our flexibility to a diverse array of product types and clients: from rebuilding hotels and commercial districts after natural disasters, to our expansion into complex industrial projects in the 20th century, to solidifying our place as a modern-day industry leader in sustainable mass timber construction.

Today, Swinerton is proud to provide premier commercial construction services to nearly 20 market sectors. Several of these markets—including Healthcare, Life Sciences, Affordable Housing, Aviation, and Parking Structures—comprise a large portion of our portfolio in multiple regions nationwide, necessitating centralized resources. These sectors are also essential to our daily lives, serving our society’s needs for health, shelter, and transportation.

To address the unique demands of these markets, Swinerton has centralized its resources and appointed National Market Leads to guide the overall focus and approach, enhance the consistency of project delivery from region to region, and reduce onboarding time for project teams by equipping them with the right training, resources, and processes to deliver on specialized market-specific needs.

To address the unique demands of these markets, Swinerton has centralized its resources and appointed National Market Leads to guide the overall focus and approach, enhance the consistency of project delivery from region to region, and reduce onboarding time for project teams by equipping them with the right training, resources, and processes to deliver on specialized market-specific needs.

“A national approach enables effective management, ensuring that we allocate resources where they are needed most,” says Chris Morris, leader of Swinerton’s National Healthcare market. “Recognizing that each division has its unique strengths and challenges, our team provides tailored support to address these specific needs. Whether it involves delivering in-depth healthcare market research, assisting with project management, or offering targeted training and development, we reduce the learning curve for local divisions and ensure that their teams are equipped with the necessary tools and resources to thrive.”

While projects across the country will always have regional considerations, such as different code requirements and jurisdictional agencies, many markets also have specific inherent industry needs that must always be considered no matter the project size, location, or complexity. For example, research-focused clients often operate in regulated, complex industries and require partners who understand the critical nature of their work, says Swinerton’s National Life Sciences Director, Marcella Ayala.

“From an operational perspective, Swinerton provides a solid backbone through centralized resources, including specialized MEP expertise and technical support, quality assurance, and safety protocols. These resources ensure that no matter where our Life Sciences clients’ projects are located, they receive the same high level of service and technical excellence that their industry demands,” Marcella adds.

As clients seek to answer what is next for their growth—whether rapidly expanding their own operations, or advancing their industry with new innovations—having a national, enterprise construction firm with the capabilities to answer a diverse set of needs is critical.

In addition to national quality and safety programs and centralized MEP expertise, Swinerton is capable of self-performing some of the most critical trades that drive a project, including concrete and drywall. In addition, the firm brings extensive mass timber expertise alongside the partnership of its mass timber affiliate, Timberlab. These capabilities can help drive cost and schedule efficiencies for many market sectors, but have proven especially valuable for affordable housing, where budget, community engagement, and sustainability are at the heart of nearly every project.

“Self-perform plays a huge role in this work,” says Patrick Otellini, Swinerton’s National Affordable Housing Director. “We have struck a delicate balance between complying with the Local and Small Business Enterprise goals for these projects, while identifying solid scopes of work for our self-perform group to help drive down cost and create schedule efficiencies. We also interface a lot with Timberlab, since many of these clients are looking at ways to build more sustainably.”

Recently, a Seattle-based architect who helped author changes to the 2021 International Building Codes (IBC) collaborated with Swinerton and Timberlab to build Seattle’s first mass timber mid-rise workforce housing structure under the new codes. The partnership testifies to how Swinerton’s integrated offerings are not only advancing the future of certain market sectors, but the construction industry as a whole.

Swinerton’s ability to self-perform work is also critically tied to the success of one of its largest national platforms: parking structures. Rather than a market in and of itself, Director of Parking Structures Jeff Goodermote refers to the structures he constructs as a specific “product” that intersects with and supports every other market that Swinerton works in.

“The parking structures sector is a little different from other market sectors, which may include different product types all under one umbrella. For example, aviation has landside and airside operations. Healthcare has acute and non-acute facilities. Compared to those markets, parking is a truly specialized, niche field,” Jeff says.

The group’s complete expertise in parking structure products can be largely attributed to the success of Swinerton’s self-perform concrete group, he adds.

“We have invested in a substantial amount of self-owned concrete formwork that is specific to concrete parking structures. Leveraging our design-build or progressive design-build expertise, we can design a parking structure around our specific formwork, which often results in a considerably lower price than market rate,” Jeff continues. “We have even shipped our formwork over the Pacific Ocean to deliver concrete projects in Hawaii. In addition to our extensive collaboration with our self-perform concrete teams, we are beginning to engage our drywall teams to self-perform some of the fa?ade treatments of our parking structures to round-off our thorough, end-to-end expertise in this product type.”

Over the past decade, the National Parking Structures group has delivered on a number of aviation parking structures throughout California and Colorado, not only bolstering its own portfolio but also the project experience of the National Aviation group. This has been a catalyst for success in other divisions, such as Texas and the Southeast. Additionally, intergroup collaboration between Swinerton’s national market platforms allows the firm to leverage its focus on enhanced efficiency, knowledge-sharing, and commitment to drive value by bridging often-fragmented scopes of work.

“Airport decision-makers are looking for partners who can be problem-solvers that understand both the complex requirements of airport construction and the unique aspects of the local market. We are thrilled to regularly partner with other Swinerton target markets like National Parking Structures,” says Carrie Shaeffer, National Director of Aviation.

“Clients benefit from a collaborative approach because we can provide innovative parking expertise and capabilities that also align with the specific nuances of sensitive airport environments informed by our National Aviation group,” Jeff adds.

Modern construction is demanding. Through our national market platforms, Swinerton ensures that our regional teams have the skills, resources, and support they need to tackle projects in a wide range of sectors. Furthermore, our coast-to-coast expertise and capabilities provide opportunities for clients seeking consistency and efficiency in their project delivery nationwide.

The post Delivering Crucial Infrastructure on a National Scale appeared first on Swinerton.

]]>Mass Timber Buildings: A New Approach to Sustainability and Net Zero Goals

Mass timber is quickly becoming a solution as the number of public institutions and private developers pledging to attain net-zero carbon emissions increases. Whether they are leaning on public-private partnership (P3) or traditional delivery methods, owners and developers are recognizing the benefits of wood as a versatile, sustainable, and structurally efficient feature for their projects. With public and private support for this renewable resource, experts believe mass timber could challenge steel and concrete as favored construction materials.

“Mass timber offers cost and value considerations that developers and clients see as benefits. Mass timber supports regional economies, saves time on the speed of construction, and is a renewable resource—with the added benefits of improved daylighting and interior aesthetics, which benefits the health and well-being of the end-user as well,” said Swinerton Builders (Swinerton) Pacific Northwest Regional Director of Preconstruction William Silva.

For example, at Northlake Commons, the utilization of mass timber estimates 1,990 metric tons of avoided CO2e (carbon dioxide equivalent) emissions, with a total carbon benefit of 2,920 metric tons; this is equivalent to removing 558 cars from the road or to the energy required to operate 249 homes for an entire year. It is also estimated that forests in the U.S. and Canada can regrow the equivalent wood volume in four minutes.

Swinerton’s early commitment to mass timber began in 2016 with the design, permitting, and construction of the then largest mass timber office building in the U.S.—First Tech Federal Credit Union Oregon Corporate Campus—which was delivered four months faster and four percent cheaper than structural steel.

In a short period, Swinerton has become known for taking on and successfully delivering some of the most challenging mass timber projects in the country. With the number of mass timber projects expected to double every two years, Swinerton has assembled an unparalleled knowledge base and robust internal resources that are sought after by design teams and owners who want to capitalize on the lessons learned from other projects.

While building designs will continue to push toward net zero energy, reducing operational carbon through better energy efficiency and cleaner energy sources, there is growing policy and regulation emphasizing the importance of reducing the embodied carbon of our infrastructure as well. Structure and foundation make up over half of a building’s embodied carbon footprint, so they are often targeted first for reductions. Every metric ton of wood used in place of concrete and steel in the structure is estimated to avoid 3.9 metric tons of CO2 emissions, and this is compounded by the fact that mass timber buildings are lighter and reduce the carbon (i.e., concrete) in the substructure.

Life-cycle assessment (LCA) is the industry tool for evaluating the embodied impacts of a building design, but what it cannot account for is the potential carbon “storage vault” mass timber infrastructure offers cities. Mature forests are maximizing their carbon storage, while growing forests are maximizing their carbon sequestration. By sustainably harvesting trees off the landscape and storing that carbon in wood structures for the life of the buildings, forests are allowed to sequester carbon more rapidly from the atmosphere and avoid releasing a large portion of the carbon stored in the removed trees.

While the softer benefits of mass timber, sustainability, and aesthetics frequently lead project teams to want to use a mass timber solution, the construction benefits are often what enables them to happen.

Swinerton recognizes the challenges of developing a project around a new structural system and brings its expertise to teams seeking creative solutions to make a mass timber project financially viable. Swinerton’s approach is to direct efforts toward reducing overall construction cost through smart and informed selections of not just the structural system but also to look at how to leverage complementary benefits in building mechanical, electrical, envelope, and interior systems to help achieve low energy goals.

“We can control costs through early assessment on project alignment with building code and efficient structural layouts that allow for complementary benefits with other building systems and maximize prefabrication,” added Silva.

Because Swinerton is a national leader in numerous construction market sectors, it combines market sector knowledge with mass timber advantages to bring beneficial outcomes for its clients. Swinerton has pioneered mass timber solutions in market sectors, including affordable housing, aviation, civic, community college, corporate accounts, healthcare, higher education, life science, office and more.

5 Examples of Swinerton’s Mass Timber Project Experience

Northlake Commons, Seattle, WA

Swinerton’s Northlake Commons highlights the sustainability of mass timber in workplace construction. This 275,000-square-foot, LEED? Platinum-certified building incorporates mass timber columns, beams, and cross-laminated timber (CLT), showcasing how renewable materials can support both structural durability and environmental responsibility. Built in collaboration with Timberlab, a Swinerton affiliate, Northlake Commons’ timber was carefully chosen for its capacity to age beautifully while creating a warm, health-focused environment. Mass timber, significantly lighter than concrete and steel, reduces carbon emissions by up to 75%.

Beyond the use of wood, the building’s design maximizes water and energy savings, contributing to a 27% reduction in electricity usage and conserving over 700,000 gallons of water annually. Further, a significant 96% of construction waste was recycled, minimizing environmental impact. This commitment to sustainable mass timber not only enhances the building’s aesthetic and structural integrity but also reinforces Northlake Commons as a model for eco-friendly development in modern architecture.

Childcare Center, Boise, ID

The new 19,347-square-foot single-story childcare center is a groundbreaking example of the benefits of mass timber in early education. Imagine nine lively classrooms with stunning vaulted ceilings, where clerestory windows flood the space with natural light, accentuating the warmth of timber columns and beams. Outside, timber overhangs create inviting play areas, blending seamlessly with nature.

This center isn’t just beautiful—it highlights sustainability. It combines mass timber with additional eco-friendly exterior materials, native landscaping, and cutting-edge energy-efficient features like low-VOC paint, smart thermostats, and LED lighting, seeking to achieve LEED? Gold certification. This innovative approach ensures a healthy, inspiring environment for children to learn and grow.

Sunnydale Community Center, San Francisco, CA

A vibrant new 30,000-square-foot neighborhood community center is a stunning two-story mass timber marvel. It offers a mix of spaces, such as a teaching kitchen, study areas, a recording studio, and a living room for community gatherings. The Sunnydale Community Center also hosts new facilities for Boys & Girls Clubs of San Francisco and Wu Yee Children’s Services, significantly boosting their capacity to provide childcare and youth programs.

Designed for LEED? Gold certification, the center emphasizes sustainability and biophilic design, using CLT and glulam for structural, aesthetic, and eco-friendly qualities. The exposed wood structure not only speeds up construction but also reduces waste and creates a warm, inviting atmosphere.

This project revitalizes the neighborhood, demonstrating the potential of mass timber construction and environmental responsibility with beautiful, impactful construction.

Live Oak Bank Building 4, Wilmington, NC

In Wilmington, NC, a new development is welcoming employees—a four-story, 67,000-square-foot constructed entirely from mass timber. This ambitious project is one of the largest of its kind in the United States, slashing the building’s carbon footprint by up to 60%. Nestled among trees and overlooking an expanded pond, Live Oak Bank Building 4 is a harmonious blend of nature and innovation. The design incorporates numerous biophilic elements, aiming to foster a happier, healthier, and more productive work environment. The building is on track to achieve LEED? Silver certification, highlighting its commitment to sustainability and eco-friendly design.

In Wilmington, NC, a new development is welcoming employees—a four-story, 67,000-square-foot constructed entirely from mass timber. This ambitious project is one of the largest of its kind in the United States, slashing the building’s carbon footprint by up to 60%. Nestled among trees and overlooking an expanded pond, Live Oak Bank Building 4 is a harmonious blend of nature and innovation. The design incorporates numerous biophilic elements, aiming to foster a happier, healthier, and more productive work environment. The building is on track to achieve LEED? Silver certification, highlighting its commitment to sustainability and eco-friendly design.Responsive Arts & STEAM Academy, Denver, CO

Additional Reading: Contractors are Partners for Achieving Sustainable Development Goals

The post Mass Timber Buildings: A New Approach to Sustainability and Net Zero Goals appeared first on Swinerton.

]]>WE ARE MASTER BUILDERS

Swinerton planted roots as a builder 135 years ago, and continues to deepen them nationwide. Alongside our subsidiary companies, we leverage our knowledge, skills, and drive to build the projects and workforce of the future. We take pride in the expertise and passion it takes to raise a structure from the ground up. Because, at our core, we are builders.

A CHANGING INDUSTRY

When brick mason Charles Lindgren founded the company that would become Swinerton at the end of the nineteenth century, the construction landscape looked very different than it does today. The industry was moving from a workforce of individual craftspeople managed by an architect or engineer to a more centralized system. Positions like those of superintendent and foreman emerged to be the expert eyes on the jobsite to manage installation and supervision, while contractor builders brokered materials, labor, and services.

An entrepreneurial mason turned builder, Lindgren saw the potential for greater speed and efficiency as technologies like steel-reinforced concrete emerged on the market. His business partner, Lewis A. Hicks, was a vocal advocate for this technology—writing two enthusiastic articles in 1905 for The Architect and Engineer of California and distributing brochures on the topic to local engineers.

When tragedy struck in the form of the 1906 San Francisco earthquake, Lindgren and Hicks were completely equipped to help rebuild, and could legitimately claim that their steel-reinforced concrete buildings fared better than most in the devastation. Clients who were initially skeptical of the “newfangled” material were convinced. By 1908, when namesake Alfred B. Swinerton joined the firm, the company was well on its way to becoming

one of the most recognized builders in the West, thanks in no small part to its expertise in concrete.

SEEING POTENTIAL

In the century that followed, Swinerton has continually invested in enterprises and people to keep the industry moving forward, expanding its markets and offerings nationally and internationally. From engineering canals and pipelines in the 1950s, driving value-add services like tenant improvements in the 1980s, to embracing sustainable materials and energies in the 2020s, we are always finding ways to build where the world is going.

In 2016, Swinerton recognized another opportunity: to drive construction forward by adopting mass timber. As a result, our mass-timber specialist subsidiary was launched in 2021, harnessing the structural and environmental potential of engineered wood materials and helping clients meet their vision for sustainable structures that soar with the beauty of timber.

BUILDERS OF TOMORROW

Being a master builder depends on first-hand knowledge of the builder’s craft, which must be passed down with each generation. We continue our 135- year builder’s legacy by supporting the workforce of the future: training the next generation of craftspeople in trade skills, and attracting more builders to the industry.

Through The Swinerton Foundation’s support of trade education programs at the Cypress Mandela Training Center in Oakland, CA, Portland YouthBuilders in Portland, OR, and The Roc in Charlotte, NC, partnership with organizations like SkillsUSA nationwide, and outreach efforts at colleges and universities, we are driven to support the young people who will become our next generation of master builders.

OUR BUILDER’S LEGACY

Alongside the industry’s evolution, at Swinerton we continue our master builder’s legacy through the present day, employing thousands of expert craftspeople on staff as laborers, journeymen, foremen, and superintendents whose direct experience in the field ensures our projects’ success. As a company, we invest in their safety, their training, and their well-being to ensure their expertise shines on every project.

Swinerton Builders’ self-perform teams include concrete, drywall, doors, frames and hardware, carpentry, millwork, and demolition and clean-up. Our family of companies also includes a broad range of professionals whose expertise encompass concrete at SAK Builders, mass timber at Timberlab, and engineering, procurement, and construction of renewable gas plants at Swinerton Energy.

On every project, we also draw on our experts who understand the non-physical components of building: financing, logistics, planning, permits, site entitlements, and more. Our administrative teams at Swinerton, Lindgren Development, and Griffin Swinerton work in tandem to make our clients’ buildings possible.

Combined with our expert knowledge and skill, our pride of ownership, passion, leadership, integrity and excellence are what truly make us master builders.

The post We are Master Builders appeared first on Swinerton.

]]>WHY MASS TIMBER IS EARNING A PLACE IN HEALTHCARE CONSTRUCTION

HEALTHY BUILDINGS FOR A HEALTHY PLANET:

Original Post: 12/2022 | Revision 2 06/20/24

The use of?mass timber?in commercial building projects continues to double in growth each year as a low-carbon, sustainable and light-weight structural material compared to traditional construction materials. Mass timber was already popular in Europe, which accounts for over 60% of the global market for this innovative construction material, but its adoption is now becoming increasingly widespread across North America. According to the Wood Products Council, as of March 2024, 2,115 multi-family, commercial building, and institutional projects featuring mass timber are underway or completed in the United States, reflecting a steady growth trend.

Mass timber is prized by architects, builders and environmentalists alike. When exposed in building designs, the material’s beauty is immediately apparent. As a structural element, mass timber can meet or even exceed concrete and steel construction performance standards. Its most important benefit, however, is its potential contribution as a climate change solution.

While steel and cement manufacturing are among the world’s largest sources of carbon emissions, a mass timber-framed building can serve as a carbon sink throughout its lifetime, sequestering carbon absorbed from the atmosphere while the wood was growing in the forest. As long as the building stands, the carbon contained in the wood remains locked in the structure and will not be released into the air.

“Conversations around sustainability in the building industry used to be focused on operational energy, the carbon emissions associated with a building’s use from heating and cooling, for example,” said Tanya Luthi, director of engineering at Timberlab. “That understanding has evolved to include the full life cycle of a building, including the embodied carbon of the materials used to construct the project. Fortunately, advancements in engineered wood products, such as the development of cross-laminated timber, have coincided with a strong and deepening commitment to sustainable forestry practices, allowing us to use mass timber responsibly at scale from an engineering and a sustainability perspective. Wood is the only major structural material that we can regrow.”

Because of these climate benefits, governments and municipalities across the U.S. and worldwide are establishing policies that promote the use of mass timber in new construction. A recent example is New York City’s Mass Timber Accelerator program, which is piloting the use of mass timber in a series of large-scale construction projects across the city to align with its decarbonization efforts.

At the same time, many jurisdictions are revising building codes to permit the use of mass timber in ways that previously wouldn’t have been considered. These changes have enabled the construction of revolutionary new buildings like the Ascent in Wisconsin. At 25 stories and 284 feet tall, this residential tower in the heart of Milwaukee’s downtown is the world’s tallest hybrid mass timber building.

Despite the rapid growth in enthusiasm for mass timber construction across multiple industries, the healthcare sector has been slower to adopt this climate-friendly material. Concerns about medical space planning, infection control, acoustics and vibration suppression — among other issues — have inhibited the healthcare industry’s transition to mass timber structures.

However, this reluctance is fading as new projects — including an ambulatory care unit in Sechelt, British Columbia and Northlake Commons, a life sciences laboratory and workspace building in Seattle — demonstrate mass timber’s enormous potential to revitalize the construction of healthcare facilities. Besides mass timber’s obvious environmental benefits, its use is also proven to contribute to patient and employee well-being and bolster the brand reputation of its earliest adopters.

In the months and years to come, it will be increasingly important for leading organizations in the healthcare industry to demonstrate their commitment to the health of the planet and their communities by choosing the building material that best aligns with their mission — to improve human health.

WHY MASS TIMBER? THE GROWING FOCUS ON SUSTAINABILITY, SOURCING TRANSPARENCY AND ETHICAL BUILDING AND CONSTRUCTION

Among stakeholders in healthcare, as well as a broad array of other industries, there is growing awareness of the climate impact of constructing new buildings and facilities. World Green Building Council estimates that the built environment is responsible for 39% of global carbon emissions. Cement and steel manufacturing industries account for nearly 10% of the world’s ongoing carbon emissions, a source of carbon dioxide that’s difficult for societies to eliminate. On average, approximately 2 tons of carbon dioxide are emitted in manufacturing every ton of steel, though this can be reduced somewhat by incorporating scrap into recycled steel production.

In contrast, trees capture and store carbon as they grow — approximately 1 ton for every cubic meter of growth. By weight, trees are approximately 50% carbon. When trees are harvested, all the carbon that has been sequestered in the wood while they were growing remains there. Once that harvested wood is used in a building that carbon will stay within that structure for as long as the building stands. In essence, mass timber construction projects transfer sequestered carbon from forests to the built environment. Then, new trees are replanted in place of those harvested, capturing and storing yet more carbon.

This fact accounts for the environmental promise of mass timber construction. Mass timber is a renewable resource. Plus, it’s possible to store embodied carbon within a building for the whole of the structure’s lifecycle. Research indicates that mass timber construction is approximately 50% more carbon-efficient than steel.

But this is a rule-of-thumb estimate. The actual climate impact of any individual mass timber construction project will be influenced by the forestry, transportation and milling practices employed for the wood used in the project, as well as how the building is disassembled and its materials disposed of at the end of its life cycle.

For a truly sustainable building project, using locally sourced wood from sustainably managed forests is necessary. Not only do intact forest ecosystems sequester more carbon, but they also help protect biodiversity and wild animal habitats. It’s key to cultivate transparency and accurate tracking in the mass timber supply chain to ensure that building materials are sourced from responsibly managed forests.

For instance, sourcing wood for building projects in the Pacific Northwest from forests in the same region makes sense because it reduces the distance construction materials need to be transported, thereby reducing emissions. This practice also supports the region’s historically important timber economy and rural communities, which are integral to the timber supply chain.

In addition, it’s crucial to select timber harvested from timberlands that grow trees to a size large enough to ensure that the maximum rate of carbon sequestration has occurred on those forested lands. Timber producers that exceed state Forest Practices Act guidelines for sustainable forestry practices and watershed health adhere to climate-smarter practices.

MASS TIMBER IN OUTPATIENT HEALTHCARE FACILITIES: AN IDEA WHOSE TIME HAS COME

To date, mass timber has not been widely used for structural systems in healthcare industry construction projects. This means there are few examples to validate that mass timber can meet healthcare facilities’ unique structural requirements. However, research and innovation are underway, and ongoing studies demonstrate that mass timber can meet the strength and performance requirements necessary for its adoption in healthcare.

VIBRATION CRITERIA

Buildings in the healthcare sector must meet strict vibration requirements to support the performance of critical operations and sensitive medical equipment. Typically, this means that structures are designed to be stiffer and more robust, adding material and expense to the project. Vibration performance in mass timber buildings can be challenging due to the structure’s lightweight, so healthcare operators are wondering if mass timber structures can meet the requirements. New vibration analysis tools, coupled with field testing of occupied buildings, have shown that mass timber-framed structures, just like steel structures, can be designed to meet or exceed the vibration criteria for operating and treatment rooms, patient rooms, administrative and public areas, medical offices and lab areas.

ACOUSTIC REQUIREMENTS

Sounds in healthcare environments can range from the beeping of alarms and equipment to the hum of machines and HVAC systems to other people’s conversations. These can irritate or even harm patients, and transferring these sounds can violate patient privacy required by HIPAA (Health Insurance Portability and Accountability Act). Healthcare facilities require conscious design for strategic sound control, and mass timber elements have lower sound ratings because of their lower mass relative to concrete. For this reason, timber panels are complemented by other materials in a floor assembly that can add mass and ensure noise control. Laboratory tests have shown that mass timber floor assemblies can achieve acoustic performance that meets industry guidelines.

INFECTION CONTROL

Healthcare facilities have strict surface-cleaning and sanitization requirements, particularly in high-risk areas such as operating rooms and intensive care units. In these areas, surfaces must be resistant to microbial growth and spread, smooth, nonporous and durable enough to withstand repeated cleaning and disinfection. In critical facilities such as surgical suites in mass timber buildings, wood can be encapsulated with materials and finishes that create a sterile and durable surface, like what is done in concrete and steel buildings. In less critical facilities, the wood can be coated with a washable finish.

FIRE PREVENTION AND SUPPRESSION

There’s a common misconception that wood is inherently dangerous in fires. However, mass timber is not a lightweight wood frame construction, and like a log in a campfire, mass timber buildings have inherent fire resistance due to their size. Though still a combustible material, mass timber structures are designed and built to achieve the same fire and life safety requirements as non-combustible construction.

In fact, cross-laminated timber and glulam members have demonstrated compliance with local and international building codes. Unlike steel, which will lose strength if it becomes too hot, mass timber building components will incur surface charring but retain strength to sustain design loads. In addition, mass timber beams and columns designed to inhibit floor-to-floor and room-to-room smoke transfer have earned smoke ratings comparable to those of steel structural elements. Fire risks in mass timber buildings can be additionally mitigated with encapsulation or through other compensating measures, such as improved egress design, more reliable and robust suppression systems and early fire detection measures.

COST CONCERNS

In the past, some stakeholders have avoided mass timber because they perceive it as inherently more expensive. While it can be true that there are higher material costs associated with building and framing in mass timber, these costs are generally offset by shorter material lead times, faster structure installation, and a shortened construction schedule overall.

“Timber structures can be built faster, but that is only advantageous when projects are planned and managed correctly. The biggest financial risk in any construction project will always be the labor cost, which is highly dependent on how much time the project takes. Delays are generally more expensive than changing materials, resolving conflicts or altering designs. Mass timber project timelines are more predictable, which makes the capital investment more predictable,” states Erik Benedetti, project manager and healthcare lead at Swinerton.

Some stakeholders have also avoided using mass timber because of concerns about the cost or availability of insurance. Because this is an emerging technology, not all insurers may understand mass timber’s performance and benefits. It may be necessary to engage and communicate with your underwriter to help them understand and accurately assess the risks. This issue will almost certainly become rarer as mass timber adoption accelerates.

ENSURING BETTER PATIENT EXPERIENCES TO IMPROVE CARE OUTCOMES

Healthcare stakeholders increasingly recognize that providing high-quality patient care goes beyond supplying the right medications, technologies and evidence-based therapeutic protocols. Optimizing patient outcomes also requires providing care that respects individuals’ preferences, emotional needs and values. It means treating patients in spaces purposefully designed to make occupants feel healthy and safe. In this arena, mass timber construction truly shines.

The aesthetic and design benefits of exposed wood in architecture are already well understood. As award-winning architect Michael Green, who builds mass timber structures in British Columbia, said, wood is “nature’s fingerprint in buildings,” so mass timber has a deeply soothing effect on the buildings’ occupants.

Biophilic design is among the latest trends in hospital and healthcare facility design. A growing body of research shows that incorporating natural elements or views of nature in healthcare facilities can improve staff productivity and efficiency while enhancing patients’ feelings of well-being, decreasing stress levels and reducing pain levels. Studies have shown that hospital patients whose rooms have views of forested land or water recover more quickly than those with views of a blank wall. They require less pain medication and leave the hospital earlier. Mass timber construction with exposed structural elements can bring that impression of nature into the healthcare facility. Plus, if patients are told the building’s story, they’ll understand the positive impact its construction has had.

“Awareness of the impact of climate change is growing among patients today,” said Chris Morris, director of national healthcare at Swinerton. “Knowing that the building where you’re receiving care was built from materials that were sourced locally, that are more sustainable and that are contributing to sequestering carbon from the atmosphere is significant for many people. The beauty of mass timber is just one more reason they’d prefer to receive care in those buildings.”

While leading healthcare organizations are designing healthcare spaces to feel welcoming, artful and beautiful rather than sterile or clinical, they’re also thinking about ways to extend the benefits of design aesthetics to their employees. In a field where record shortages of nurses and other skilled professionals are an acute problem, it’s particularly important to design employee break rooms and common spaces in ways that are restful and calming to help counter burnout.

Furthermore, patients and employees alike appreciate when a healthcare organization’s commitment to sustainability and ethical building practices allows it to operate harmoniously with its mission of promoting human health and healing.

CONCLUSION

Today’s healthcare organizations face numerous challenges. They must recruit and retain top-notch care providers, deliver high-quality patient care and streamline operations to manage costs. To build thriving practices that will attract patient populations now and continue to do so in the future, they must demonstrate that they care for the minds, bodies and spirits of patients, caregivers, administrators and visitors. This requires more than medical expertise; it also demands vision and the courage to make sustainable and ethical choices.

“The stakes are high in an industry like healthcare – we are talking about people’s lives,” said Luthi. “When the stakes are high, people are often cautious about change, which could be one reason we haven’t seen mass timber adopted as widely in healthcare as in other sectors. But if you look at it another way, incorporating mass timber into healthcare projects is actually the perfect opportunity to make a positive impact both on the planet and on its people.”

The post WHY MASS TIMBER IS EARNING A PLACE IN HEALTHCARE CONSTRUCTION appeared first on Swinerton.

]]>Swinerton Welcomes Inland Northwest Native as Senior Estimator

Travis Bradford will spearhead preconstruction and estimating efforts, elevating client services.

Swinerton is proud to announce the newest addition to its Inland Northwest team, Travis Bradford. As the first estimator dedicated solely to the division, he will lead the team’s preconstruction, estimating, and business development efforts.

With an impressive 24 years of local industry experience and a Bachelor of Science in Construction Management from Washington State University, Bradford brings valuable expertise and familiarity with alternative delivery projects, including GC/CM. His diverse career spans from being a laborer to owning his own construction company, which has honed his ability to envision projects piece-by-piece, analyze risk, and develop practical, innovative solutions to common construction challenges.

“Travis is an instrumental hire for our Inland Northwest team here at Swinerton,” says Jeremiah Shakespeare, Swinerton’s Inland Northwest Vice President and Division Manager. “He brings a strong reputation as both a manager and estimator and embodies the Swinerton values of passion, integrity, excellence, leadership, and ownership. We are excited to continue building our preconstruction and estimating services around him as we strive to serve our clients.”

Bradford’s arrival marks another milestone in the ongoing success of Swinerton’s Inland Northwest team. The company has been constructing successful projects with corporate services clients in the region for nearly a decade. It opened its permanent office in Spokane in 2019 to develop its local relationships and market footprint further. The team continues strengthening its expertise in design-build and GC/CM projects, positioning Swinerton as a sought-after construction leader in office spaces, healthcare and life science facilities, aviation, educational institutions, hospitality, and affordable and multi-family housing.

The post Swinerton Welcomes Inland Northwest Native as Senior Estimator appeared first on Swinerton.

]]>SWINERTON ADDS INLAND NORTHWEST CONSTRUCTION VETERAN, STRENGTHENING POSITION IN THE INLAND NORTHWEST

Lori Porath joins Swinerton as Senior Project Manager

(Spokane, WA) Swinerton, a leading nationwide construction manager and general contractor, is proud to announce the newest addition to its Inland Northwest team. Lori Porath, a seasoned construction veteran, will leverage over 30 years of experience in the industry to bolster Swinerton’s position in the region’s commercial construction market and enhance its trade partner relations.??

?

Joining the firm as Senior Project Manager, Porath brings a wealth of local knowledge and expertise in alternative delivery projects, including GC/CM, and a passion for building innovative learning environments within the education sector. Since earning her Bachelor of Science in Civil Engineering from the University of Idaho, her career has taken her across different locations, including Coeur d’Alene, ID; Southern California; Seattle, WA; and Hawaii. However, her heart has always been in the Inland Northwest.??

?

“Having Lori join our team is a significant step forward for us,” says Jeremiah Shakespeare, Swinerton’s Inland Northwest Vice President and Division Manager. “Her extensive experience, local knowledge, and dedication to delivering exceptional construction projects align with Swinerton’s values.”??

?

Throughout her construction career, Porath has managed over $500 million in commercial projects ranging from $50,000 to $50 million. Notably, she takes pride in her work in the education sector, where she has led K-12 projects like Mountainside Middle School in Spokane and Lincoln Middle School in Pullman, WA. Her experience also extends to higher education, where she has managed projects on the Washington State University campus in Pullman. With over half of her career dedicated to the education sector, Porath’s contributions have positively impacted countless students and educators in the region.?

?

However, Porath’s talents are not limited to education. Since joining Swinerton, she has showcased her versatility by leading the North Valley Hospital Mechanical, Electrical, and Plumbing Upgrades in Tonasket, WA. Located 163 miles northwest of Spokane, the crucial project involves coordinating trade partners to upgrade the hospital’s critical systems, ensuring seamless access to ongoing medical services. This highly technical project requires careful coordination and accurate work sequencing, as the hospital must remain operational during all construction activities.?

?

Lori Porath’s arrival comes as Swinerton’s Inland Northwest team continues to thrive. Following several years of successful projects with corporate service clients in the region, Swinerton opened a permanent office in Spokane in 2019. With a strong focus on design-build and GC/CM projects, Swinerton has emerged as a sought-after construction leader in various sectors, including office spaces, healthcare facilities, educational institutions, hospitality, and affordable and multi-family housing.?

?

“As we mark the fifth anniversary of our Inland Northwest Division, which has a regional history of over 15 years in construction projects, adding Lori to our team enhances our capabilities and contributes to our continued growth. Based in Spokane, our Inland Northwest Division has achieved positive growth in revenue, expanded our geographic reach, and, importantly, our people have flourished with 100% employee-ownership, dedicated to serving our valued clients,” adds Shakespeare.?

The post SWINERTON ADDS INLAND NORTHWEST CONSTRUCTION VETERAN, STRENGTHENING POSITION IN THE INLAND NORTHWEST appeared first on Swinerton.

]]>City of Pasco and Burnham RNG Partner to Modernize Wastewater Treatment

Burnham RNG LLC (Burnham) announced today the issuance of green bonds to support the construction of the Pasco Resource Recovery Center (PRRC), an innovative industrial wastewater treatment facility that will clean wastewater for agricultural re-use and capture biogas and convert it into renewable natural gas (RNG). The bonds were issued by the Washington Economic Development Finance Authority and the private placement was led by Jefferies LLC. The bonds were issued a Baa3 rating by Moody’s and a Green Bond designation with an external review from Kestrel.

The project represents a 30-year public private partnership with the?City of Pasco?for Burnham to build, own and operate the PRRC on behalf of the City. The RNG will be sold under a long-term contract, allowing the City to reduce net treatment costs and take advantage of tax incentives currently available for RNG projects under the Inflation Reduction Act. The center will support the growth of the City’s booming agribusiness sector while turning wastewater into clean energy and providing clean water and nutrients to irrigate and fertilize City-owned farmland.

The project is being constructed under an EPC contract with Swinerton Builders, Inc. and will feature two Evoqua low-rate anaerobic digesters and an innovative nitrogen reduction system provided by Gross Wen Technologies.

The post City of Pasco and Burnham RNG Partner to Modernize Wastewater Treatment appeared first on Swinerton.

]]>Trauma-informed design guides Excelsior project

The Excelsior Wellness Center LLC renovation in Spokane is a nonprofit organization focused on providing comprehensive behavioral health services to patients in the local community. The renovation project is being carried out in three phases, with Swinerton serving as the general contractor for the entire project.

For the Excelsior Wellness Center renovation, Swinerton’s team is working in a live environment, which requires careful planning and coordination to ensure that ongoing operations are not disrupted. The company is employing best practices to minimize disruption to the center’s patients and staff, including segregating construction areas, limiting noise, and ensuring that all work is completed within the agreed-upon schedule.

Swinerton’s team is incorporating the latest technology and construction methods to ensure that the project is completed efficiently and to the highest standard. The company is using Building Information Modeling (BIM) software to create 3D models of the renovation, allowing the team to identify potential issues and conflicts before construction begins. This approach helps to reduce waste, lower costs, and minimize delays, ultimately leading to a more successful project.

Swinerton’s work on the Excelsior Wellness Center renovation is an excellent example of the company’s commitment to delivering high-quality projects that meet the unique needs of its clients. The company’s experience in healthcare construction, combined with its technical expertise and sustainability practices, makes it an ideal partner for projects of this kind.

The post Trauma-informed design guides Excelsior project appeared first on Swinerton.

]]>